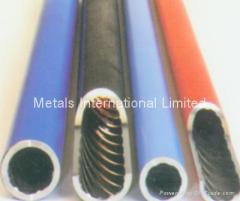

Helical Welded Pipe

| Place of Origin: |

, China (Mainland) |

Product Detail

API 5L Line Pipe (Grade B X42, X46, X52, X56, X60, X65, X70, X80)

ISO 3183 Steel Pipe for Pipelines

ASTM A500

ASTM A252

AS1579

ASTM A-134

OD | W/T | inch | mm | inch | 8-5/8 | 219.1 | 0.203-0.344 | 10-3/4 | 273.1 | 0.203-0.500 | 12-3/4 | 323.9 | 0.219-0.500 | 14 | 355.6 | 0.219-0.562 | 16 | 406.4 | 0.219-0.562 | 18 | 457 | 0.219-0.562 | 20 | 508 | 0.219-0.562 | 22 | 559 | 0.219-0.625 | 24 | 610 | 0.219-0.625 | 26 | 660 | 0.219-0.625 | 28 | 711 | 0.219-0.625 | 30 | 762 | 0.219-0.625 | 32 | 813 | 0.250-0.751 | 34 | 864 | 0.250-0.751 | 36 | 914 | 0.250-0.751 | 38 | 965 | 0.250-0.751 | 40 | 1016 | 0.250-0.751 | 42 | 1067 | 0.250-0.751 | 44 | 1118 | 0.250-0.751 | 46 | 1168 | 0.250-0.751 | 48 | 1219 | 0.250-0.751 | 52 | 1321 | 0.250-0.751 | 56 | 1422 | 0.250-0.751 | 60 | 1524 | 0.250-0.751 | 64 | 1626 | 0.365-0.851 | 68 | 1727 | 0.365-0.866 | 72 | 1829 | 0.365-0.866 | 76 | 1930 | 0.365-0.866 | 80 | 2032 | 0.365-0.866 | 84 | 2220 | 0.365-0.866 | 95 | 2420 | 0.365-0.866 | 100 | 2620 | 0.365-0.866 | 115 | 2820 | 0.365-0.866 | 120 | |

| | |

|

| |

| Specifications | API 5L Line Pipe (Grade B X42, X46, X52, X56, X60, X65, X70, X80)

BS 3602 Steel Pipe and Tubes for Pressure Proposes Carbon Steel: High Duties.

DIN 17172 Stahlrohre fur Fernleitungen fur brennbare Flussingkeiten und Gase( Pipe for cross country pipelines for flammable liquid and gas)

ISO 3183 Petroleum and Natural Gas Industries-Steel Pipe for Pipelines-

DNV OS-F101 Submarine Pipeline Systems

JIS G 3444

JIS G 3445

JIS G3452

ASTM A 513

ASTM A211-85

ASME SA211

ASTM A500

ASTM A252

AS1579

ASTM A-134

ASTM A-139

AWWA C-200

CAN/CSA Z245.1

STN 42 0144

STN 42 5738

DIN 1615:1984 "Welded circular tubes of non-alloy steels without special quality requirements"

DIN 1626:1984 "Welded circular tubes of non-alloy steels with special quality requirements"

CSN EN 10208-1:2000 "Steel tubes for pipeline for combustible liquids" - part 1: Requirements according to class A

CSN EN 10208-2:1999 "Steel tubes for pipeline for combustible liquids" - part 2: Requirements according to class B

DIN 17120:1984 "Welded circular tubes of non-alloy steels for steel constructions"

DIN 17172:1978 "Steel tubes for pipeline for transport of combustible liquids and gases"

DIN 1628:1984 "Welded circular tubes of non-alloy steels with very high quality requirements"

EN 10217-1:2002 "Welded steel pipes for pressure purposes"

EN 10219-1:1997 "Cold formed welded structural hollow sections of non-alloy and fine grain steels"

EN 10220:2002 "Seamless and welded steel tubes - General tables of dimensions and masses per unit length"

ISO 4200:1989 "Plain-end steel tubes, welded and seamless"

CSN 42 5738:1979 "Spiral weld steel pipes"

DIN 2458:1981 "Welded steel tubes"

EN 10219-2:1997 "Cold formed welded structural hollow sections of non-alloy and fine grain steels"

Coating Specifications:

Epoxy Coating: DIN 30670, CAN/CSA Z245-M92

Fusion Bonded Epoxy Coating: AWWA C213

2LPE/3PE Coating: DIN 30670, CAN/CSA Z245, TS 5139, NFA A49-710 UNI 9099

Polyurethane Coating: BS 5493

Lining: AWWA C210, TS 5140

ISO/DIS 21809, Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems - Part 1: Polyolefin coatings (3- layer PE and 3- layer PP)

Part 2: Fusion-bonded epoxy coatings

GOST 8696:1974 "Electrically welded steel pipes with spiral seam"

PN 79/H-74244:1979 "Welded steel pipes for transportation of media" |

|

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com